ANALYSIS: New Zealand rules governing the steel that goes into highways, bridges and tunnels are much looser than in Australia.

Regulation tightened up recently across the Tasman and the Australian Steel Institute said that was in response to substandard products causing problems before 2011, with damaging cyclones exposing weaknesses in some products.

It means Australian state roading agencies have more control over which steel mills and fabricators are used for major projects.

Photo: Wikicommons

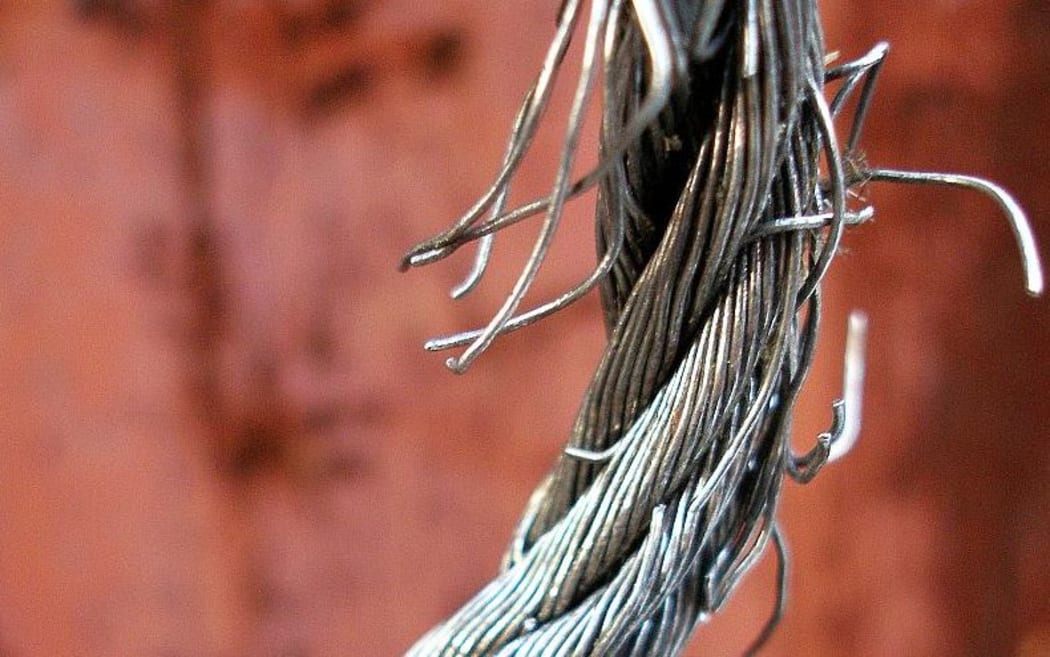

For example, when it comes to the purchase of steel strand, a type of wire rope that gives bridge and tunnel concrete its tensile strength, in New Zealand the transport agency (NZTA) takes the lead and sets the rules, but in Queensland it is the Department of Transport and Main Roads or (TMR).

Importing and manufacturing

New Zealand:

When RNZ asked the NZTA how a supplier was chosen for the steel pile casings on the Huntly Bypass that failed it said it was up to the main contractor and was not its business.

Typically the process goes like this: The main contractor picks a subcontractor and looks to transfer the risk to that subcontractor. Cost is the major consideration; in private projects price often carries a 70 percent weighting when tenders are compared, possibly a bit less than that in public projects such as roads.

The subcontractor then goes to a trading company in, for example, Australia.

The trading company takes that order to a factory in, for example, China - sometimes combined with lots of other orders to try to get a better price for a bigger volume.

The factory does not have to meet any standards set by the NZTA; in fact, it may not know where the steel came from.

In the Huntly Bypass case, the importer, Steel & Tube, is understood to be looking at taking legal action, but it is not clear if that's against the trading company or the factory.

Queensland:

The importer is held responsible for the state of the steel. Only a very limited number of importers are approved by the TMR after demonstrating they can manage the quality control from the factory.

Other suppliers can no just roll up and get steel for Queensland's roads.

In addition only certain factories are approved. In the case of steel strand, just four an Australian manufacturer, a Chinese, Thai and a South African company.

To get on that list, each factory undergoes 18 to 24 months of testing and scrutiny.

They also must be certified by the Australian Certification Authority for Reinforcing Steel (ACRS) which not only audits factory quality but makes sure its processes and products meet Australian and New Zealand standard. Local standards are, for instance, very particular about earthquake-reinforcing requirements.

New Zealand's Transport Agency does not require ACRS certification.

Testing

To stay on Queensland's approved list each year a factory must:

Give the TMR test reports, including for a test on the strand that lasts 1000 hours and is the foundation for all the other testing - that is what is demanded by the standard AS/NZS 47672.

Some of the strand coils that have already been tested for 1000 hours are then sent to Brisbane for independent 1000 hour testing at Queensland University's laboratory for comparison.

In New Zealand, in the Huntly Bypass case of steel pile casings, the Chinese test certificates were wrong. Steel & Tube said it had tests done at the factory - which it would not name - and by an internationally-accredited lab - which it would not name.

In Queensland, for steel strand, the approved importer must ensure each shipment has had all its coil tested at the factory - which is ACRS certified to the AS/NZS Standard and that 15 percent of each shipment has been independently tested - and passed - at a laboratory that itself is accredited.

In China it would be a CNAS-accredited lab, as CNAS is recognised by Australia's main test watchdog, the National Association of testing Authorities (NATA).

The importers also demand full traceability so they know the actual billet of steel used at the mill from which the strand came.

Installing

All of the above leads to installation of the strand to make the concrete strong enough. For that, the documents that come from the factory and importer are crucial.

The AS/NZS 4672 standard says test certificates must show the coil number so that builders can keep a record of what steel strand they are installing where in case there are any problems.

In Queensland the importers carry the can and keep a very close eye on the factory. They will usually have a relationship with that manufacturer going back several years and send their own inspectors in to check at each step of each shipment.

"We've been doing this for years and we still have to keep a very close eye on them," said one. "We are continually conducting ongoing testing to maintain it."

Queensland's tight controls limit competition, so that probably pushes up what the state government pays for roads and those controls might also constrain innovation.

The system is also not flawless; a 2014 report from the TMR, Reducing the Cost of Infrastructure, includes half a dozen photos illustrating the sort of bad roadbuilding it is trying to combat.