The price is going only in one direction, and that’s down.

Justin Hodgkiss, MacDiarmid Institute

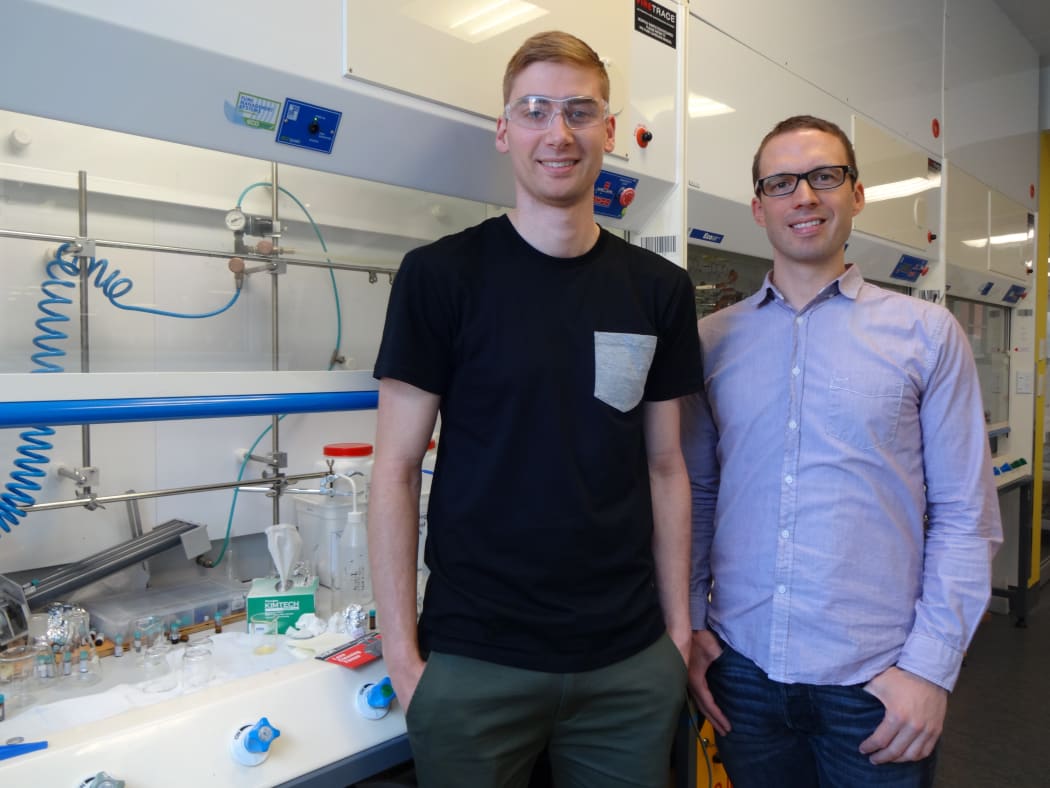

Justin Hodgkiss, on the right, leads a team at Victoria University that focuses on polymer-based solar cells. Joe Gallagher, left, is currently completing his PhD. Photo: Veronika Meduna / RNZ

This year we’ll capture more of our energy from sunlight than ever before. Photo-voltaic panels are part of a thriving renewables industry, and the drive to reduce greenhouse gas emissions to tackle climate change is likely to boost growth even more.

Justin Hodgkiss, the deputy director of the MacDiarmid Institute, says as production is scaled up, costs go down, and we could be on the cusp of a solar revolution that makes solar power affordable and competitive.

“Solar power has been doubling every two years, but it’s not something that’s come out of the blue. It’s actually been doubling every two years for the past 25 years, ever since photo-voltaic panels were first invented. This is completely normal scaling for a new technology.”

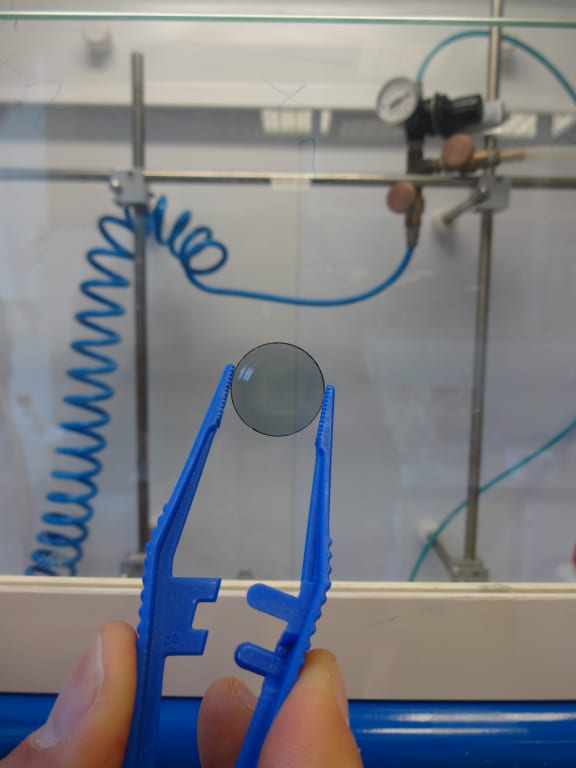

This disc has been coated with a thin film of a light-absorbing polymer solution, which could be printed on flexible surfaces. Such polymer-based solar cells could be mass-produced in a process similar to printing newspapers. Photo: Veronika Meduna / RNZ

At Victoria University of Wellington, Justin Hodgkiss leads a group that focuses on the next generation of polymer-based printable and flexible solar cells, which have the potential to bring prices down even further because they can be mass-produced and are made of abundant materials.

In my lab, we’re working on printable PV technology and that is where the active layer that absorbs light and creates electricity, instead of being made from silicon which you need to process as a solid panel, it’s made from polymers that can be printed as an ink.”

Joe Gallagher, who is completing a PhD in the group, says the polymers are dissolved in solution and can be printed as a very thin film that can be put on a flexible, transparent substrate.

“The layer can be incredibly thin, so you don’t need much material to effectively act as a solar cell. One kilogram can spread over 5000 square metres so you’ve got a very efficient way of making a lot of photo-voltaic cells for very low cost in terms of the materials, but it’s all about finding the most efficient materials.”

Chemically speaking, the polymers are complex molecules whose electrons are arranged in a way that allows them to absorb light and conduct electricity. Their structure is similar to chlorophyll, the green pigment plants use in photosynthesis.

The team works with chemists around the world who synthesise promising materials, which are then put through their paces in a laser lab in a quest to identify those that are most efficient in converting light into electricity.

The team uses ultra-short laser pulses that are about 100 femto seconds long (a millionth of a billionth of a second), says Justin Hodgkiss. “The reason we need such short pulses is that the time scale that light is converted to electricity is on that timescale. The difference between a good polymer photo-voltaic material and a bad polymer PV material happens on the sub-pico second timescale and so we’ve been focusing hard on that time scale to find out exactly what makes a good charge separation.”

And that’s where efficiency gains come from. In essence, the first step in creating a current comes down to absorbing light and separating positive and negative charges.

I’m quite optimistic that we’re going to get over 15 per cent power conversion efficiency. To put that into perspective, the silicon panels that you would buy today for your roof are about 15 to 16 per cent efficient. When I first started working on polymer PV, the efficiency was about 4 per cent seven years ago. Now it’s at 12 per cent and that’s been through the type of iterative process whereby measurements from labs feed into the design of new molecules.”

If we were to scale up solar power, Justin says the materials required to make the active layers are abundant. “I would say that the things that we would need to think carefully about and possibly innovate new solutions are other components, like the electrodes."

Active layers need to be sandwiched between electrodes and one of those needs to be transparent. “There are challenges in generating electrodes that are cheap and made from abundant materials but I’m sure that these innovations will go hand in hand with the development of active layer materials."

Justin Hodgkiss is one of the speakers in the Royal Society of New Zealand’s Luminaries series, which marks the International Year of Light.